HOLLEY DUAL CARBURETORS IN-CHASSIS ADJUSTMENTS

HOLLEY DUAL CARBURETORS IN-CHASSIS ADJUSTMENTS

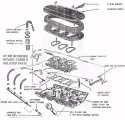

Idle Fuel Mixture Adjustment

1. Operate the engine until it reaches normal operating temperature. If the car is equipped with an air conditioner, the engine must be operated at least 20 minutes. All engine speed and idle fuel mixture adjustments must be made with the air cleaner installed.

2. Establish an initial idle fuel mixture adjustment by turning both idle mixture screws on each carburetor (Fig. 5) inward until they are lightly seated. Then turn the idle mixture screws on each secondary carburetor (Fig. 6) outward 3/4 turns, and turn the primary carburetor idle mixture screws outward one full turn.

Fig. 5

|

Fig. 6

|

3. Install an engine speed tachometer. Start the engine; move the transmission selector lever to the DRIVE (Dl) position, and set the parking brake. Adjust the engine idle rpm to 575-600 rpm by turning the idle speed adjusting screw (Fig. 5) on the primary carburetor only.

4. Turn the primary carburetor idle mixture screws inward until the engine begins to run rough from the lean mixture. Turn the mixture screws outward until the engine begins to roll from the rich mixture. Turn the screws inward until the engine runs smoothly and evenly. Always favor a slightly "rich" idle fuel mixture.

5. Repeat this procedure (step 4) to adjust the idle mixture screws on the front secondary carburetor.

6. Following the same procedure, adjust the idle mixture screws on the rear secondary carburetor. The right and left idle mixture screws on any one carburetor should be open an equal amount, within 1/8 turn, after the final adjustment.

7. With the engine operating at idle and the transmission in Drive range, check the engine speed. The tachometer should indicate 575-600 engine rpm.

8. If the engine still does not idle properly, due to a too rich mixture, i.e., idle mixture screws are seated, it may be caused by improper initial idle speed setting of the secondary carburetors. Also, if the throttle levers are not synchronized, it will be difficult to obtain a satisfactory idle adjustment.

IDLE SPEED ADJUSTMENT

All engine speed and idle fuel mixture adjustments

must be made with the air cleaner installed

and the engine at normal operating temperature.

1. Back off the idle speed adjusting screw (Fig. 5) on each secondary carburetor sufficiently to allow the throttle plates to seat in the throttle bores. Turn the idle speed screws inward until the screw end just touches the stop on the throttle lever; then turn it inward an additional 1/2 to 3/4 turns. A minimum throttle opening is desired on the secondary throttle plates. The only requirement necessary is that the plates do not stick in the bores.

2. Operate the engine for 30 minutes at 1200 rpm to normalize engine temperatures. Install an engine speed tachometer. Start the engine. Move the transmission selector lever to the DRIVE (Dl) position, and set the parking brake. Adjust the engine idle rpm to 575-600 rpm by turning the idle speed adjusting screw on the primary carburetor only.

3. Set the fast idle speed (cold) with the engine at normal operating temperature. Align the high step on the fast idle cam with the adjusting screw (Fig. 7) . Turn the screw inward to increase or outward to decrease the idle speed to obtain the specified rpm.

Fig. 7

THROTTLE LEVER SYNCHRONIZATION

If the throttle linkage is disassembled or it is improperly synchronized,

the following procedure is recommended for synchronizing

the throttle levers on the three carburetors.

1. Insert a 1/8-inch diameter rod through the gauging holes (Fig. 8) provided in the bellcrank lever and mounting bracket on the left side of the bellcrank assembly. This locks the lever in the gauging (closed throttle) position.

Fig. 8

2. Disconnect the secondary throttle rods at each secondary carburetor throttle lever (Fig. 5) . Disconnect the primary throttle rod at the bell-crank lever.

3. Loosen the lock nut and adjust the length of the front secondary carburetor throttle rod so that, when installed, the throttle lever of the front secondary carburetor will be completely closed when the primary throttle lever is closed against the idle speed adjusting screw stop (normal idle position).

4. Adjust the length of the rear secondary carburetor throttle rod in the same manner.

5. Install the secondary throttle rods on the secondary throttle levers with the spacer washers and retainers. Tighten the lock nuts to secure the adjustment.

6. With the primary throttle lever against the idle stop, adjust the length of the primary throttle rod (Fig. 6) , so that the trunnion will just engage in the hole in the bellcrank lever. Install the rod retainer clip.

7. Adjust the anti-stall dashpot clearance.

ANTI-STALL DASHPOT ADJUSTMENT

1. Adjust the engine idle speed and idle fuel mixture, and synchro�nize the carburetor linkage. Operate the engine until it reaches normal operating temperature.

2. Lock the throttle linkage in the gauging position by inserting a 1/8-inch diameter rod through the gauging holes provided in the bellcrank lever and mounting bracket on the left side of the bellcrank assembly (Fig. 8) .

3. Loosen the lock nut and turn the anti-stall dashpot screw in, or away from the bellcrank lever. Fully depress the dashpot plunger with a screwdriver blade, and adjust the clearance between the plunger and bellcrank lever to 1/8-3/16 inch. Tighten the locknut and remove the 1/8-inch rod from the gauge holes.

AUTOMATIC CHOKE ADJUSTMENT

The automatic choke has an adjustment to control its reaction to engine temperature. By loosening the three screws that retain the choke thermostat housing (Fig. 7) , it can be turned to alter the thermostatic spring adjustment. Turning the housing in a counterclockwise direction provides a richer mixture, and conversely, a leaner mixture is obtained by turning the housing in a clockwise direction as indicated by the arrows on the housing. Refer to the specifications for the proper setting.

ACCELERATING PUMP ADJUSTMENT

With the throttle lever (Fig. 9) held in the wide-open-throttle position and the accelerating pump arm fully depressed (manually), there should be 0.015-inch clearance between the screw head and the pump arm.

Fig. 9

Turn the adjusting screw into the screw head to increase the clearance and outward to decrease the clearance. One-half turn of the screw equals approximately 0.015 inch.

To satisfy acceleration requirements in various climates, the accelerating pump cam can be placed in either of two positions. Aligning the top hole of the cam with the top hole of the throttle lever gives the shortest stroke which is recommended -for .warm weather or average conditions. Aligning the cam bottom hole with the lever bottom hole gives the longest stroke which is recommended for cold weather operation.

FUEL LEVEL CHECK

Position the car on a level floor. Be sure the fuel pump pressure is within specifications. Operate the engine for 30 minutes at 1200 rpm until normal operating temperature has been reached. Place a suitable container below the fuel level sight plug to collect any spill-over of fuel.

With the engine stopped, remove the fuel level sight plug and gasket and check the fuel level (Fig. 10) . The fuel level within the bowl should be at the lower edge of the sight plug opening + or - 1/16 inch.

Fig. 10

If the fuel level is satisfactory, install the sight plug. Do not install the air cleaner at this time.

If the fuel level is too high, drain the fuel bowl and refill it and check it again before altering the float setting. This will eliminate the possibility of foreign material causing a temporary flooding condition. To drain the fuel bowl, remove one lower retaining bolt from the fuel bowl and drain the fuel into a suitable container. Install the bolt and start the engine to fill the fuel bowl.

After the fuel level has stabilized, stop the engine and check the fuel level.

FLOAT ADJUSTMENT

1. If the fuel level is too high, it should first be lowered below specifications and then raised until it is just at the lower edge of the sight plug opening. If the fuel level is too low, it is only necessary to raise it to the specified level; thus omit steps 3 and 4 of this procedure.

2. With the engine stopped, loosen the lock screw on top of the fuel bowl just enough to allow rotation of the adjusting nut underneath (Fig. 10) . Do not loosen the lock screw or attempt to adjust the fuel level with the engine running because the pressure in the line will spray fuel out and present a fire hazard.

3. Turn the adjusting nut approxmately Vi turn in to lower the fuel level below specifications (1/6 turn of the adjusting nut, depending on the direction of rotation, will raise or lower the float assembly at the fuel level sight plug opening 3/64 inch).

4. Tighten the lock screw. Start the engine. After the fuel level has stabilized, stop the engine and check the level at the sight plug opening. The fuel level should be below specified limits. If it is not, repeat step 3, turning the adjusting nut an additional amount sufficient to lower the fuel below the specified level.

5. Loosen the lock screw and turn the adjusting nut out in increments of 1/6 turn or less until the correct fuel level is achieved. After each adjustment, tighten the lock screw, and then start the engine and stabilize the fuel level. Check the fuel level at the sight plug opening. Install the sight plug and gasket.

6. Install the air cleaner. Check and adjust the idle fuel mixture and idle speed as necessary.

|